Wall-mounted Shelving

Our original design: timeless

Features

- Signature look: the original.

- Infinitely adjustable.

- Minimal, low-profile

- Choice of materials and finishes.

Applications

- Bookshelves

- Libraries

- Museum displays

- Offices

- Retail displays

- Closet & storage

- Kitchen & pantry

Tell us about your project when you’re ready!

Material & finish

Finishes:

- We offer custom powder-coated and anodized finishes in nearly any color.

Shelves Material:

Components

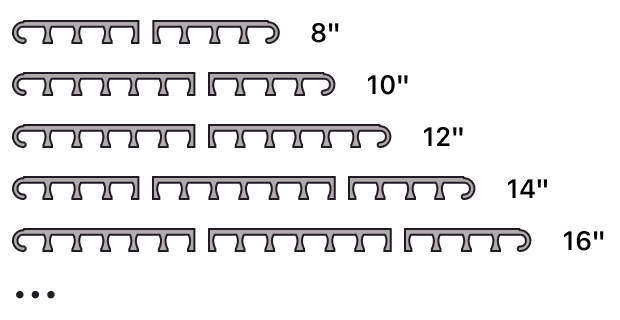

Wall Standards Go to design resources

Rakks Wall Standards feature a clean, modern look, with a continuous channel and recessed screws. No obtrusive slots or visible screw heads. Available in lengths up to 12'.

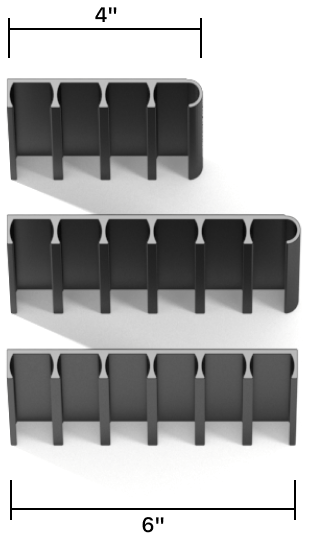

C-Standard

Most popular, minimal profile.

-

Shelves 4"-14" deep

Shelves 4"-14" deep

-

Wall Mount Recessed or Surface

Wall Mount Recessed or Surface

-

Load Standard

Load Standard

M-Standard

Decorative profile.

-

Shelves 4"-16" deep

Shelves 4"-16" deep

-

Wall Mount Surface

Wall Mount Surface

-

Load Standard

Load Standard

E-Standard

Ideal for recessed applications.

-

Shelves 4"-14" deep

Shelves 4"-14" deep

-

Wall Mount Recessed

Wall Mount Recessed

-

Load Standard

Load Standard

D-Standard

Joins shelf sections, minimal profile.

-

Shelves 4"-14" deep

Shelves 4"-14" deep

-

Wall Mount Recessed or Surface

Wall Mount Recessed or Surface

-

Load Standard

Load Standard

Q-Standard

Decorative profile, heavy duty function.

-

Shelves 10"-24" Deep

Shelves 10"-24" Deep

-

Wall Mount Surface

Wall Mount Surface

-

Load Heavy-Duty

Load Heavy-Duty

Compatible Rakks Brackets:

Rakks Style Bracket

The original Rakks bracket with a rectangular profile creates a clean, modern look.- Shelves 4"– 24" deep

- Compatibility All standards

- Shelf Material Aluminum, wood, third-party glass

- Load Capacity Up to 100 lbs of static load per bracket

Rakks T-Style Bracket

Pre-drilled flange secures wood shelf to bracket.- Shelves Up to 24” deep

- Shelf Material Wood

- Load Capacity 50-100 lbs of static load per bracket

Rakks T-Style Lab Bracket

Heavy-duty alternative to the Universal bracket.- Shelves Up to 14" deep

- Shelf Material Wood

- Load Capacity Up to 100 lbs of static load per bracket

Universal Bracket

Classic triangular bracket works best with wood shelves.- Shelves Up to 14” deep

- Shelf Material Wood

- Load Capacity Up to 60 lbs of static load per bracket

Desk Bracket

Support for work surfaces up to 24” deep. Infinitely-adjustable on all Rakks wall-mounted standards and support poles.- Load Capacity Up to 120 lbs of static load per bracket

Aria Bracket

Elegant profile for decorative applications.- Shelves Up to 14” deep

- Shelf Material Third-party glass, wood

- Load Capacity Up to 50 lbs of static load per pair

Rakks Bookshelf Go to design resources

Rakks bookshelves, though lightweight, exceed the strength and stiffness of ¾” plywood. They feature a subtly textured surface and sleek lines.

Additional Accessories: Go to design resources

-

Universal Wire Bookend

8″ wire bookend suitable easily installs into standards or poles at any point.

-

Rakks Style Bookend

Alternate with shelf support brackets in standards and poles for a classic look. Choose one size smaller than the shelf depth.

-

J-Hangbar

This stylish hangbar is designed for demanding retail and closet applications.

-

Shelf Lip

Protects walls and helps keep items in place in areas prone to earthquakes.

-

Waterfall

Used for merchandising and display, can be made to any specified length, angle and pin configuration.

Design resources

Downloadable resources for your asset library.

Ready when you are!